Branch solutions

The right solution for each industry

Our machines, marking lasers and labelling systems can be found in all industries. Whether as a standard system or as a customised special machine. – Ask us when others say “impossible”.

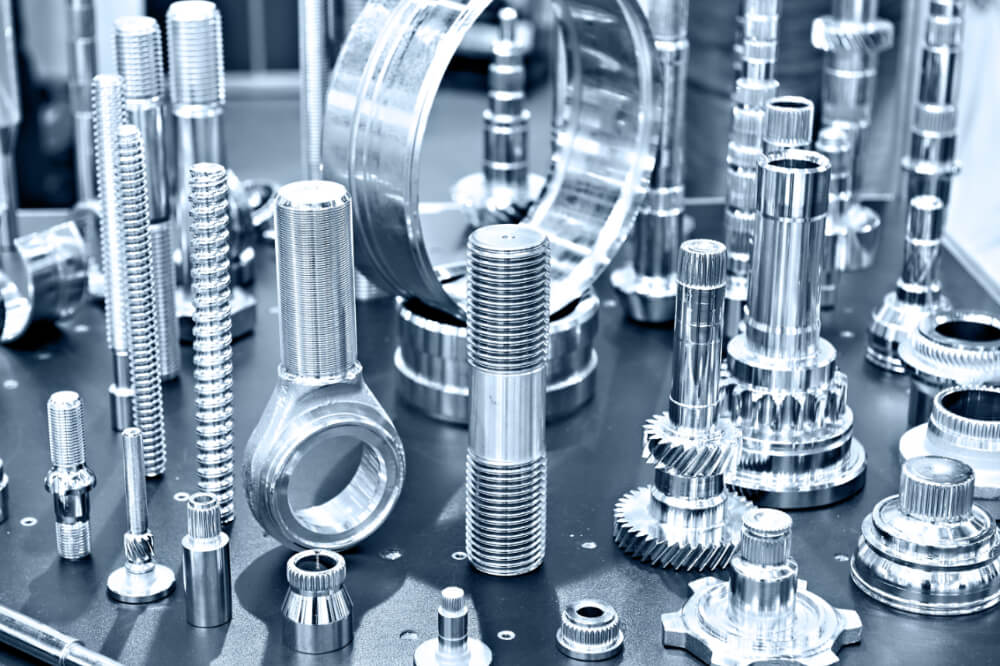

In mechanical engineering, machine units that can be easily integrated are always needed. RICHTER offers systems here which are particularly characterised by durability and robustness. However, custom-made products or contract manufacturing of machine modules are also common tasks. Diversity knows no limits here.

Whether machined with CNC machines, punched or pressed. Metals are processed everywhere across all industries and are used in a wide variety of products. Today, it is particularly important to be able to record the production chain reliably. Richter marking machines are also of great value for this.

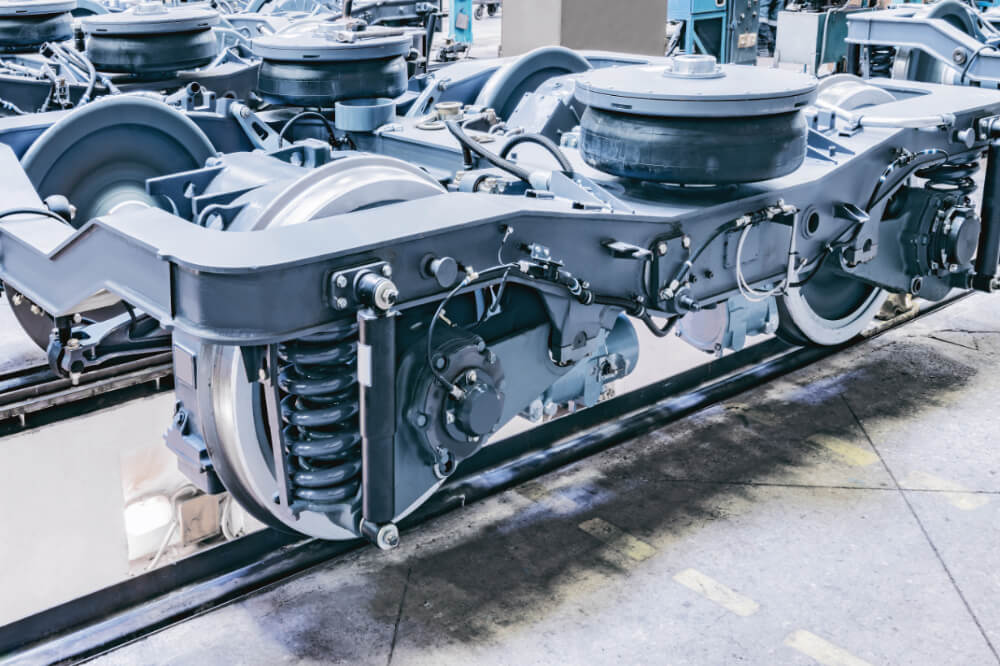

In heavy industry, robust and reliable machines are needed above all. Here, where dirt and heat cannot be avoided for production reasons, suitable systems are needed.

Years of experience at Richter are the basis for meeting these difficult requirements.

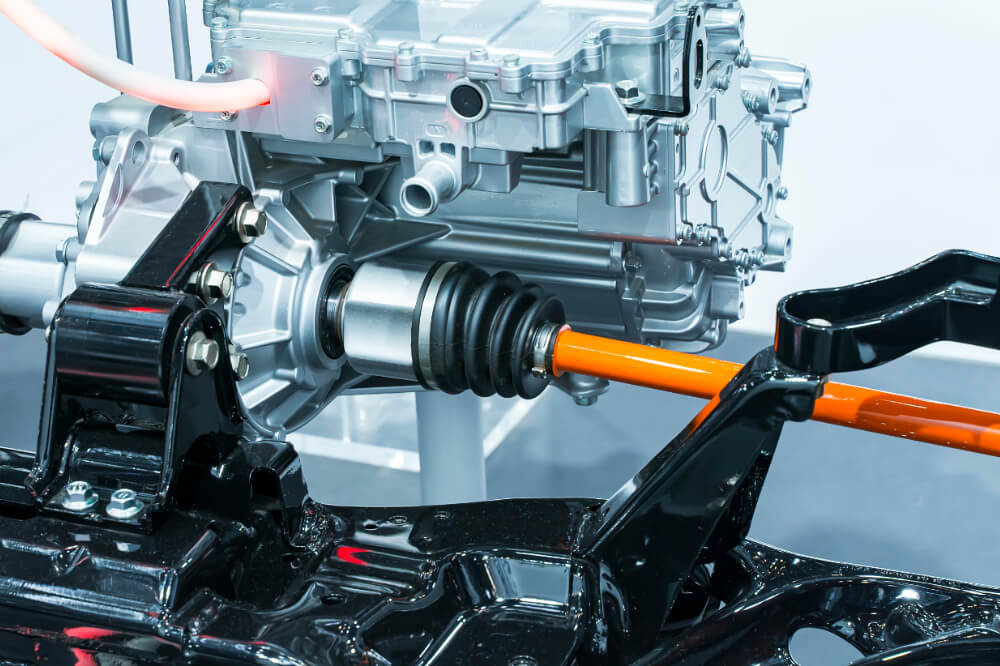

In vehicle construction, traceability is one of the most important issues. By numbering and coding all components, this can be guaranteed without gaps. Our data matrix marking systems and VIN markers, for example, make an important contribution here. We also frequently develop and build special machines and devices.

The same thing that applies to the automotive industry also applies to special vehicle construction. Whether agricultural vehicles, construction machinery, trailers, rail transport. Complete marking is indispensable everywhere.

Hardly any other industry is as demanding as the aviation industry. With machines from RICHTER, these requirements are met. In many projects implemented by us, we are able to fully meet the standard specifications.

Few industries have stricter guidelines regarding labelling than the medical industry.

Richter also offers machines and systems for production automation and labelling for this sector.

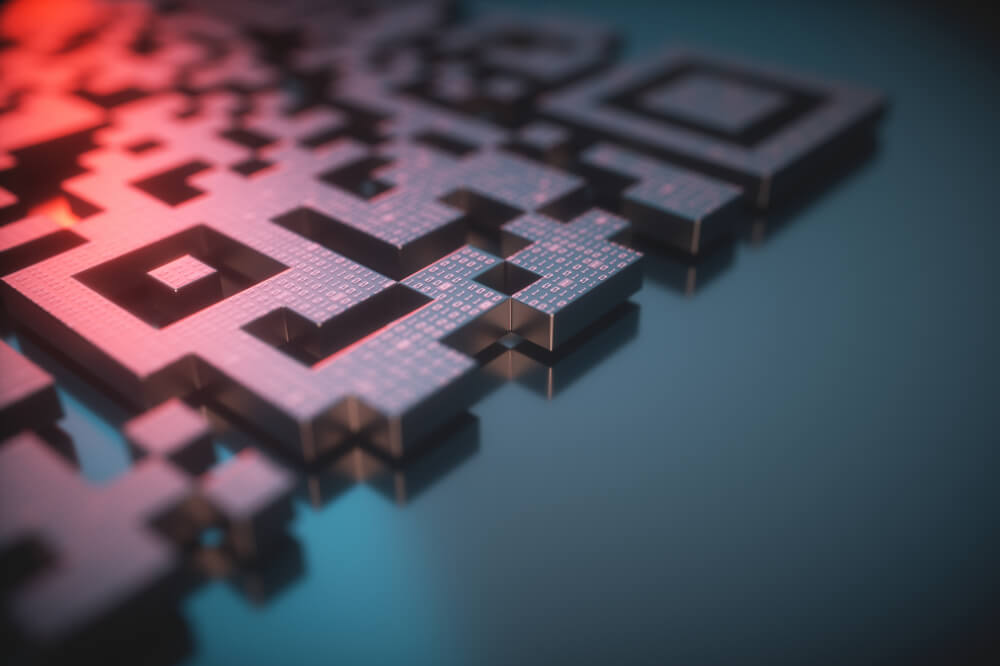

Traceability is more important than ever nowadays. In production lines built by Richter, all component information is usually carried on the RFID chip of the component carrier until the final DMC marking. This means that the production chain can be traced without interruption. In addition, it is always possible to allocate the products to the production process during subsequent operation.

The type plate is still the standard across all industries. We always offer reliable handling of all conceivable plate variants on the market.

This is also reliable when plates or labels are to be separated and applied fully automatically with short cycle times.